The cement market in Pakistan proceeds to evolve amid climbing development need and economic fluctuations.

This post gives an in-depth have a look at cement fee right now in Pakistan, value comparisons with prior months, elements influencing the market, and tendencies across numerous locations. Irrespective of whether you are a builder, contractor, or homeowner, knowing cement cost in Pakistan is important for budgeting and task organizing.

What Are The present Rates?

Exactly what is the Cement Amount in Pakistan?

The cement price in Pakistan ranges from PKR one,200 to PKR one,400 for each fifty kg bag. This fee might range depending on the cement manufacturer, area, and transportation costs. Key city centers which include Karachi, Lahore, and Islamabad are inclined to expertise a little bit larger price ranges as a result of logistical charges and greater need for cement.

In this article’s a quick overview of typical price ranges:

Brand Selling price per fifty kg Bag (PKR)

Lucky Cement one,280

DG Cement one,250

Fauji Cement one,230

Maple Leaf Cement 1,270

Dewan Cement one,200

What Factors Influence the Current Cement Premiums?

Quite a few aspects impacting cement rates Engage in a task:

Gas & Vitality Expenditures: Cement manufacturing is Electricity-intense. Fluctuations in oil and fuel costs immediately impact the price of cement in Pakistan.

Uncooked Content Availability: Critical factors such as gypsum, clinker, and limestone are becoming costlier, influencing the price of cement.

Seasonal Desire: Through peak development months (spring and summer season), cement need surges, elevating costs.

Currency Trade Amount: Imported raw components turn out to be more expensive in the event the rupee weakens from the dollar.

Authorities Policies: Obligations, taxes, and import restrictions also effect the cement price today in Pakistan.

These features collectively identify how cement selling prices shift thirty day period by month throughout Pakistan.

Cement Selling price in Pakistan: Comprehension the Market Developments

What Are the newest Cement Costs in Pakistan?

The most up-to-date cement rates in Pakistan vary involving PKR 1,200 and PKR one,400 for each bag, affected because of the brand, length from manufacturing models, and local offer chains. Cement brand names in Pakistan like Fortunate Cement, DG Cement, and Fauji Cement maintain regular top quality, which frequently justifies their premium pricing.

What exactly are the Predictions for Cement Price ranges inside the Future Months?

The cement business in Pakistan is anticipated to stay stressed from international gas selling prices and inflation. Analysts forecast that cement charges may well maximize marginally or continue being secure in coming months unless substantial alterations come about in gasoline tariffs or Uncooked material Price dynamics.

Aspects which could affect long run pricing:

Write-up-election financial reforms

Gasoline subsidy insurance policies

Global commodity prices

A stabilization or reduction in gasoline prices could lead on to lessen price today cement rate in pakistan ranges due to decreased production and logistics costs.

So how exactly does Desire Have an impact on the cost of Cement in Pakistan?

Need for cement peaks throughout active design seasons, for instance March by September. For the duration of these intervals, cement rates in Pakistan may perhaps climb resulting from minimal provide and increased orders. Conversely, off-year months can see stabilized or marginally lowered prices.

Substantial infrastructure and real-estate tasks underway throughout cities like Lahore, Islamabad, and Karachi go on to lead to robust cement desire, pushing the market toward higher costs.

Varieties of Cement Available in Pakistan: Which Need to You Choose?

What exactly are the Different Types of Cement Offered in Pakistan?

Pakistan offers A variety of cement styles catering to various development projects:

Common Portland Cement (OPC): The most often utilized form of cement for normal buildings.

Portland Pozzolana Cement (PPC): Gives enhanced longevity and resistance to chemical attacks.

Slag Cement: Created working with blast furnace slag, perfect for industrial structures.

White Cement: Aesthetic cement used in tiles, flooring, and decoration.

Hydraulic Cement: Speedily sets when blended with h2o, suitable for water-retaining structures.

These sorts of cement provide distinctive roles, and selecting the proper one particular will depend on design needs, environmental circumstances, and wanted power stages.

Michael Oliver Then & Now!

Michael Oliver Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Bo Derek Then & Now!

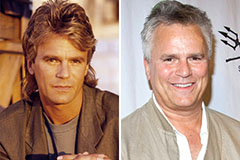

Bo Derek Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!